Microbalance

The MicroBalance™ is a high-precision micro-ingredient dosing system designed for advanced packaging lines. Utilizing AI-powered load cells and nanogram-level sensors, it ensures ±0.005g accuracy in adding flavors, preservatives, or active agents, while GMP-certified anti-vibration technology guarantees consistency in food, pharma, and smart packaging production.

Classification :

Keywords: :

Microbalance

PRODUCT DETAILS

Baojia MicroBalance™ - Full Automatic Micro-Substance Ingredient Addition System

Product Overview

The MicroBalance™ revolutionizes precision nutrition in feed production with AI-driven micro-ingredient dosing (±5g accuracy). This modular system adapts to:

- Single/Multi-Mixer Integration (1-8 production lines)

- Flexible Configurations: Choose from 10+ silo designs (50-250kg capacity)

- Closed-Loop Hygiene: FDA-grade stainless steel construction with CIP compatibility

Industry Impact:

Eliminates 100% of manual weighing errors while reducing micro-ingredient waste by 18-25% versus traditional systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Max Capacity | 250kg (customizable up to 500kg) |

| Dosing Accuracy | ±5g (single ingredient) / c3 (batch) |

| Throughput | 15-20 batches/hour (30% faster vs 2024) |

| Dust Control | HEPA-13 independent filtration |

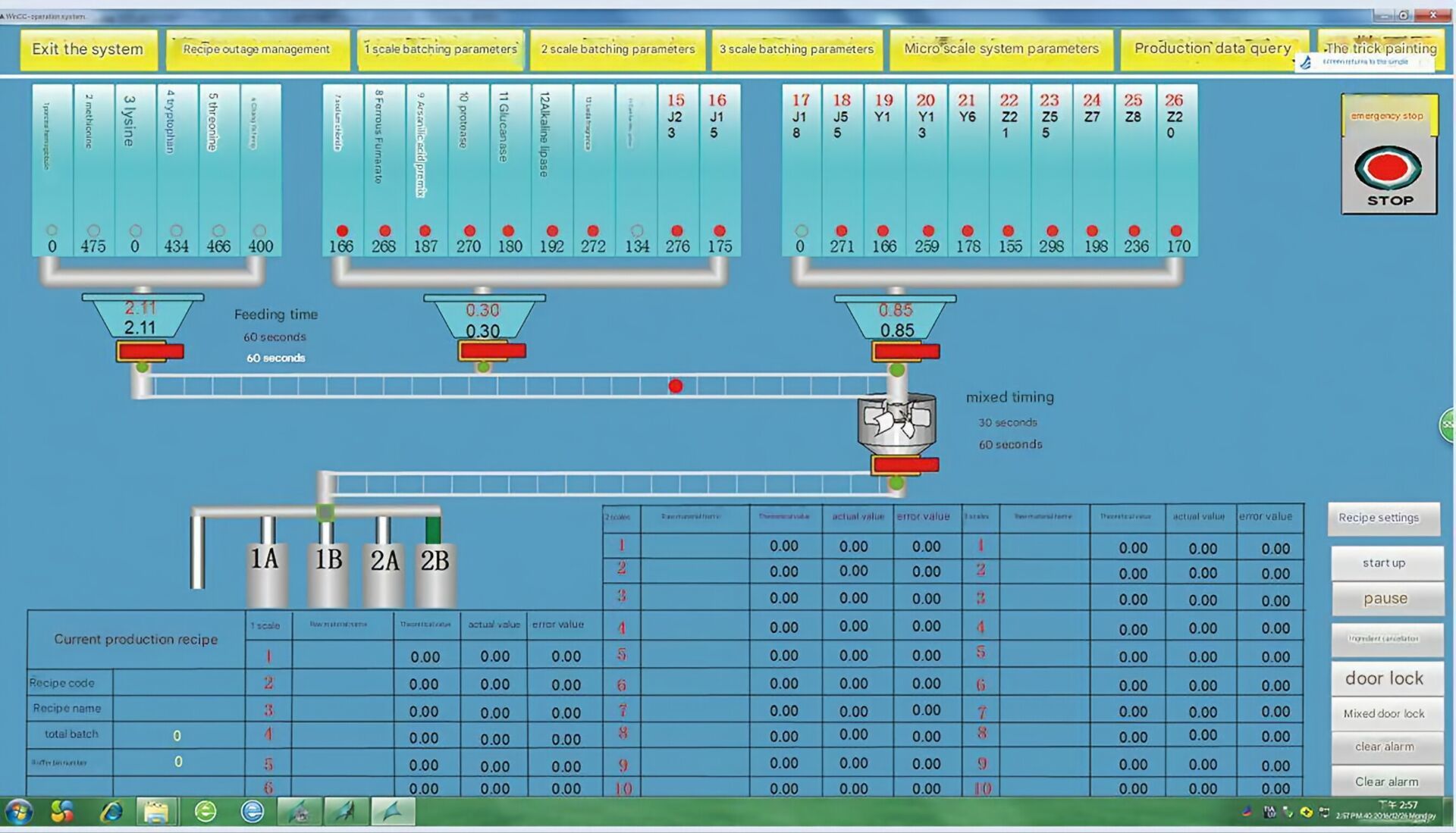

| Software | Siemens WinCC-based control platform |

5 Competitive Advantages

1. Intelligent Precision Dosing

- Multi-Speed Batching: Adjusts auger RPM based on material density (rice bran vs. minerals)

- Real-Time Alerts: LED displays show low-stock warnings & formula deviations

2. Hygienic Modular Design

- Quick-Disassembly components:

- Residue-free spiral augers

- Transparent inspection ports

- Pneumatic shakers for sticky materials

3. Future-Ready Control System

- Siemens WinCC SCADA with:

- Formula blockchain logging

- Predictive maintenance alerts

- Mobile App: Remote batch monitoring via Baoheng SmartFeed 4.0

4. Cross-Industry Adaptability

- Aquafeed: Handles astaxanthin micro-dosing (±0.1ppm)

- Petfood: Precise vitamin premixes

- Premix Plants: 99.9% traceability for EU 1831/2003 compliance

5. Ergonomic Operation

- Color-Coded UI: Follows material flow from silo to mixer

- One-Touch Calibration: <3min switch between recipes

Why Upgrade to 2025 Model?

- AI Optimization: Self-learns material flow patterns to reduce bridging

- Energy Recovery: 15% lower power consumption with regenerative braking

- Global Support: 36-hr onsite response for Tier-1 feed mills

"From 5g micronutrients to 250kg premixes – delivering accuracy at every scale."

Related Plans

GET A SOLUTION

Fill in the information to obtain a free proposal quotation, and we will contact you as soon as possible