Full Automatic Packaging Machine

Classification :

Keywords: :

Full Automatic Packaging Machine

PRODUCT DETAILS

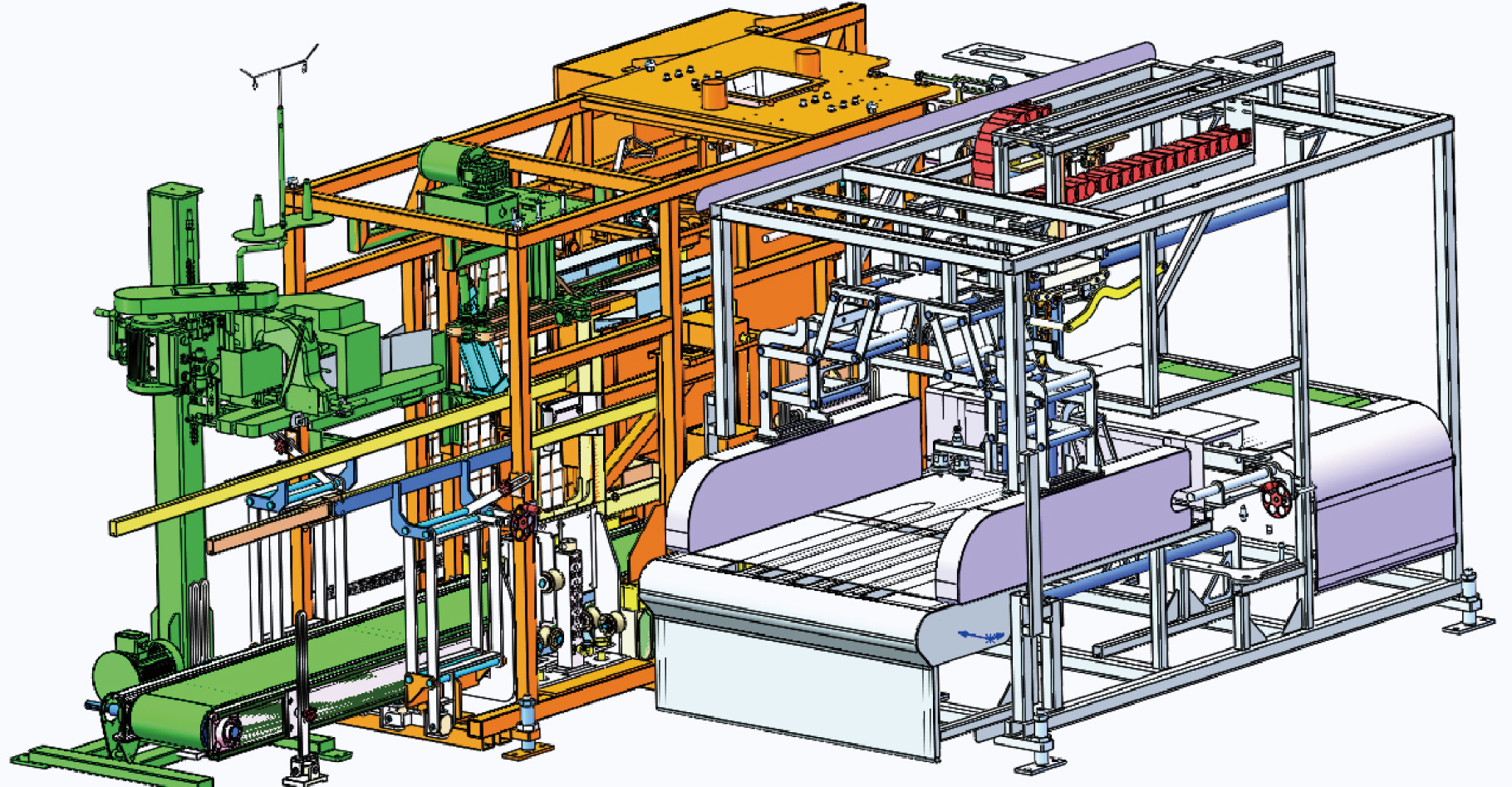

Baojia Fully Automatic Packaging Machine

As the core of intelligent packaging lines, our fully automatic system transforms manual processes into a seamless 16-step robotic workflow:

1️⃣ Auto-Bag Handling: AI-vision guided picking from 500-bag storage

2️⃣ Precision Loading: Laser-aligned filling (±0.1% weight tolerance)

3️⃣ Multi-Stage Sealing: 4 sealing modes (flat/folded/covered/hot seam)

4️⃣ Smart Labeling: RFID-enabled label application (120-140×60-75mm)

5️⃣ Finished Product Transfer: Robotic arm palletizing at 600 bags/hour

"From empty bag to pallet-ready in 45 seconds – zero human intervention after initial setup."

Technical Specifications

| Category | Specification |

|---|---|

| Operational | 24/7 operation (300 days/year uptime) |

| Throughput | 600 bags/hour (40-50kg/bag) |

| Bag Dimensions | 1000×600mm (pre-fill) |

| Label System | 500-label auto-replenishment magazine |

| Power | 6.5kW main + 2.4kW labeling (Energy Star 2025 compliant) |

| Pneumatics | 600NL/min air flow + 4m³/h labeling |

| Footprint | 2800×2300×2050mm (compact cell design) |

Key Features

1. Advanced Material Handling

- Processes granular/crushed materials (feed, flour, polymers)

- Specialized film-coated woven bags with moisture resistance

2. Premium Global Components

- Drive System: Siemens servo motors (Germany)

- Control: Mitsubishi PLC (Japan) + Delta HMI (Taiwan)

- Sensors: SICK LiDAR collision avoidance (Germany)

3. Industry 4.0 Ready

- 10" Color Touchscreen with:

- Real-time OEE monitoring (85%+ efficiency)

- Predictive maintenance alerts (50+ diagnostic codes)

- OPC UA Interface: Seamless MES/ERP integration

4. Safety & Sustainability

- Triple-Lock Protection: Emergency stop + light curtains + 95dB alarm

- Eco Mode: 20% energy reduction during idle periods

2025 Model Upgrades

♻️ AI Waste Reduction: Optimizes bag material usage by 15%

⚡ Quick-Change Kits: <3min switch between product types

📊 Blockchain Traceability: Encrypted production logs for FDA/EU compliance

"Where German precision meets Asian manufacturing excellence – redefining packaging automation for Industry 4.0."

Related Plans

GET A SOLUTION

Fill in the information to obtain a free proposal quotation, and we will contact you as soon as possible