Revolutionizing Production Lines: The Role of Fully Automatic Packaging Machines

Release time:

2025-09-11

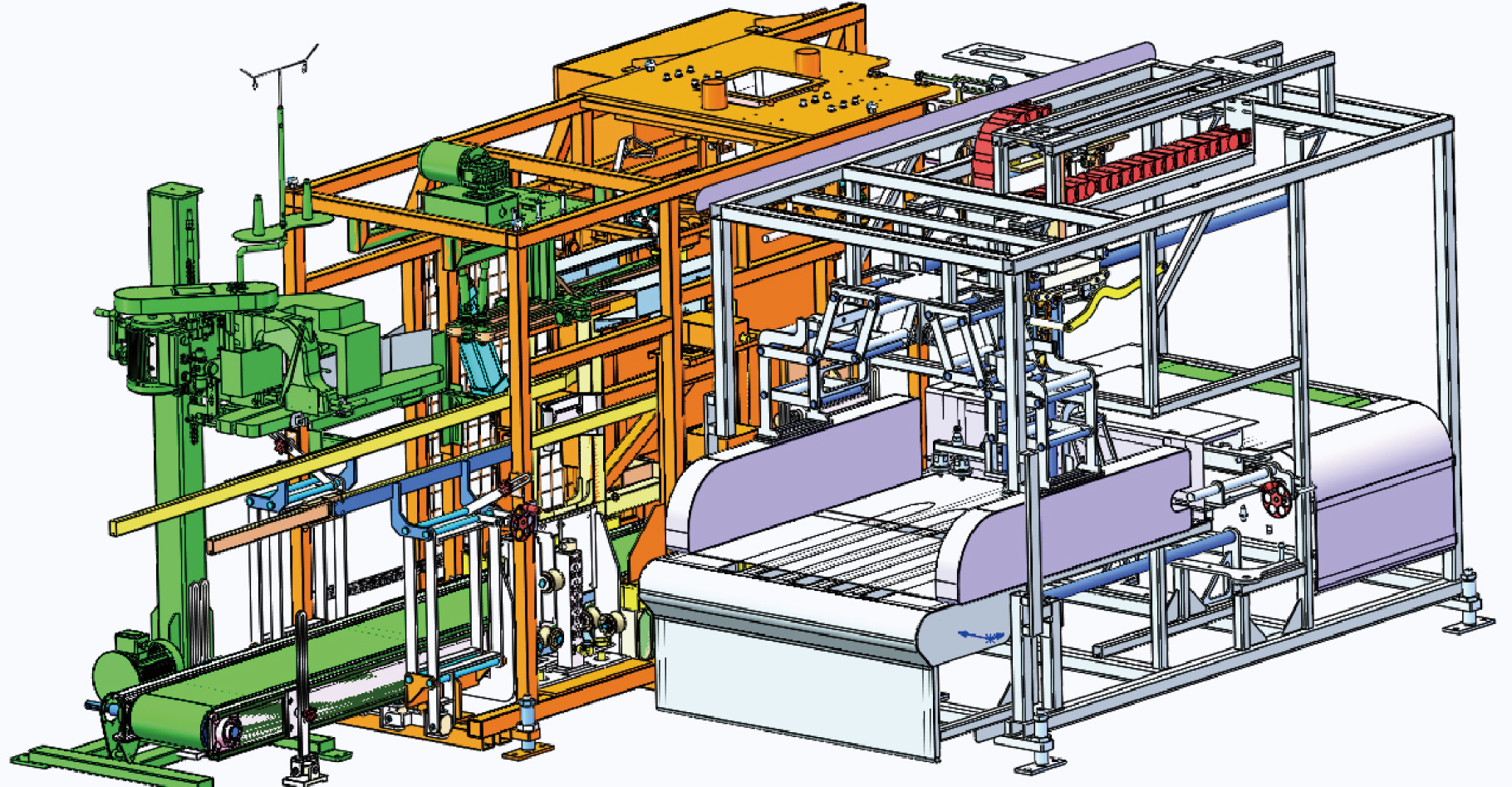

In modern industrial operations, fully automatic packaging machines have become a critical component for enhancing efficiency and ensuring consistency in output. These systems are engineered to handle a wide range of packaging tasks—from weighing and filling to sealing and labeling—without manual intervention.

In modern industrial operations, fully automatic packaging machines have become a critical component for enhancing efficiency and ensuring consistency in output. These systems are engineered to handle a wide range of packaging tasks—from weighing and filling to sealing and labeling—without manual intervention. Companies like Qingdao Baojia Automation Equipment Co., Ltd. specialize in manufacturing such equipment, integrating advanced technologies to meet diverse industrial demands.

These machines are widely applied across sectors such as food and beverage, pharmaceuticals, chemicals, and cosmetics. In the food industry, for example, they are used to package items like snacks, grains, and liquids, ensuring hygiene and precision in portion control. In pharmaceuticals, automatic packaging helps maintain sterility and accuracy for tablets, capsules, and medical supplies. Similarly, chemical and cosmetic manufacturers rely on these systems for handling powders, creams, and liquids with minimal risk of contamination or error.

A key aspect of fully automatic packaging systems is their adaptability. They can be customized to handle various materials—including pouches, bags, bottles, and boxes—and are often equipped with features like volumetric or gravimetric filling, date coding, and batch tracking. This flexibility allows production lines to switch between different products and packaging formats quickly, reducing downtime and supporting just-in-time manufacturing.

While these machines enhance throughput and reduce labor costs, their implementation requires careful planning. Factors such as product characteristics, production speed, and integration with existing machinery must be considered. Moreover, regular maintenance and operator training are essential to ensure long-term reliability.

As industries continue to prioritize automation, fully automatic packaging machines are evolving to incorporate smarter technologies, such as IoT-based monitoring and AI-driven adjustments. Companies like Qingdao Baojia are at the forefront of this innovation, providing solutions that help manufacturers stay competitive in a fast-paced market.

Latest News

Innovation Leads, Witnesses Brand Power! Baojia Intelligence Appears on “China Brand Day” in 2023

From May 10th to 14th, 2023 “China Brand Day” was held in Shanghai World Expo Exhibition and Convention Center, thousands of brand enterprises gathered together to convey the new potential of Chinese brands to the world.

2023-05-16

At the beginning of the new year, good news spreads frequently.

2023-01-12

Recently, the General Office of the Ministry of Industry and Information Technology announced the notice of “The Fourth Batch of Service-oriented Manufacturing Demonstration Enterprises List”!

2023-01-07

SMEs have traditionally been an important force for economic development. In all countries of the world, SMEs are an important part of the national economy.

2022-12-27

Stabilizing and bucking the trend

The three-day Baojia annual summary and business planning meeting came to a successful end, under the leadership of the Board of Directors, in the unremitting efforts of all management and staff and struggle.

2022-12-23

Baojia Intelligence on the List of Leading Private Benchmarking Enterprises in Qingdao in 2022

Qingdao Private Economy Development Bureau announced the “2022 Qingdao Private Leading Benchmarking Enterprises List”, and Baojia Intelligence successfully made the list.

2022-12-05